PW-20 20 Kefeli Terazi Genel Özellikler

| Titreşimli merkezi besleyici |

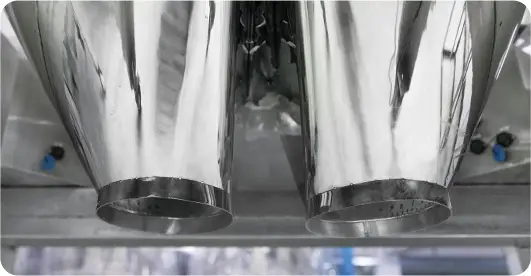

| 20 adet lineer vibratörlü besleyici |

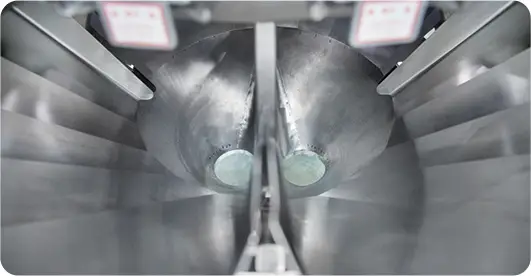

| 20 adet besleyici kefe |

| 20 adet tartım kefesi |

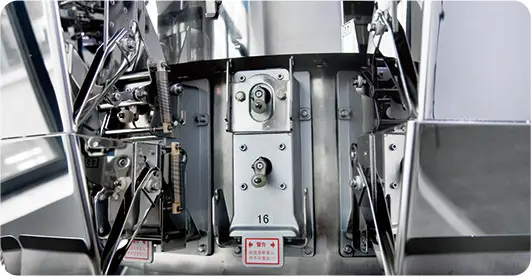

| Step motor kontrollü kefeler |

| 10” LCD renkli dokunmatik ekran |

| Kolay kullanım ve ayar |

| Bir üründen diğerine kolay ve hızlı geçiş |

| Otomatik temizlik ve ürün boşaltma |

| Büyük gramajlar için birden çok boşaltma seçeneği |

| Belirlenen tartım adedi sonunda otomatik dara |

| Ürün reçete ayarı |

| Titreşim önleyici rijit gövde |

| Komple ANSI 304 paslanmaz çelik |

| Kolay montaj, de-montaj ve temizlik |

PW-20 20 Kefeli Terazi Teknik Özellikler

| Operasyonel hız |

130 pk/dk * |

| Tartım aralığı |

10 – 1000 gr * |

| Kefe hacmi |

1.6 lt |

| Hassasiyet |

± 0.1 |

| Güç beslemesi |

AC-220V, Tek faz, 50Hz, 2 kW |

PW-20 20 Kefeli Terazi Çalışma Şartları

| Sıcaklık |

5- 35 °C |

| Nem |

30-90% |

| Kontrol paneli |

10” LCD renkli dokunmatik ekran |

| Sürücü sistemi |

Step motor |

| Load cell |

3 kg |

| Ses seviyesi |

≤ 80 db |

| Ağırlık |

~ 850 kg * |

*Teknik değişiklik yapılabilir. Ürün yapısı ve hedef gramaja bağlı değişkenler.

PW-20 20 Kefeli Terazi Opsiyonel Donanımlar

| Zamanlama Kefesi |

| Bağımsız Ürün Rejekt Sistemi |

| Load cell ile ürün seviye kontrolü |

| Döner yapıda ürün seviye kontrolü |

| Düz ve açılı besleme/vibrasyon kanalları |

| Kamera ile ürün kontrolü |

| 3 veya 4 ürün karıştırma imkanı |

| Printer veya bilgisayar ile haberleşme |

| Ürün temas eden yüzeylere teflon veya granit kaplama |

| Ürün temas eden yüzeylere perfore (arpa desen) sac uygulaması |

| Yıkanabilir su geçirmez yapı |

| 2,5lt kefe hacmi |

| Aynı gövdede 2 adet 10 kefeli terazi ile çift makine besleme imkanı |

Enhance user experience with Advanced Tabs, allowing seamless content navigation. Organize information efficiently while keeping the interface clean and interactive. Perfect for FAQs, product details, or multi-section content.